A visit to Gemfields’ Montepuez ruby mines at Mozambique unravels the humble journey of the spectacular rubies from the mines to the luxury market.

“You’re about to reach the world’s largest ruby deposits. Please do not pick any rubies and think you’ll get away unnoticed. You will be searched thoroughly at every point,” warns our guide Kanwaljit with a tongue-in-cheek smile even as our air-conditioned bus bounces through the dusty red unpaved roads leading towards the rich ruby deposits of the Montepuez Ruby Mining (MRM) mines.

A half an hour drive from MRM’s camp site brings our group, comprising media professionals and several staff members of MRM, to the gates of the vast ruby mines. Spread across 336 square kilometres, the endless stretches of rich red soil cover the wide expanse, interrupted intermittently by an occasional acacia tree looming over the stark terrain or a dense thicket of green adding a striking contrast to the red soil.

A short walk through the overgrown bushes lined on either side of the pathway leads us to an open surface where a secondary deposit of rubies is being tested and how. Ashim Roy, general manager at MRM and a geo-scientist by profession, tells us that MRM has both primary and secondary deposits, but most of the bulk sampling takes place at the secondary deposits.

Here, an auger-drilling equipment is set up and a team comprising geologists, engineers, technical experts and several workers are busy drilling the soil. Their job is to drill boreholes and remove the basement rock. The purpose of drilling is to determine the depth and thickness of the ruby-bearing gravel layer at each location. Contours of the gravel layer will be constructed from this, as well as data on the concentration of rubies. The leftovers from all samples are carefully stored and will be shifted to the soon-to-be built library for future reference and scientific study. After the process is over, the drill holes are refilled in an environmentally responsible manner to ensure the top soil is not affected.

A convoy of trucks carrying the ores are weighed and monitored all along as they move to the washing plant. Nearly thousand tonnes of ore are processed each day. Dev Shetty, COO, Gemfields, informs us that this is just the tip of the iceberg as they have explored merely 35 kilomteres of the total area (336 sq. km.) and there is enough to sustain the mining activities for another 25 years at least.

In fact, since Gemfields, the UK-based multinational company partnered with Mozambique’s Mwiriti Ltd. (stake of 75:25 per cent) to form MRM in 2011, it has displayed remarkable growth. Its inaugural auction in June 2014 of rough ruby and corundum from the deposit yielded revenues of USD 33.5 million!

With this background detail in place, the scene shifts to the ore deposits and then to the primary deposits. Mounds of red soil belie the shimmering specks of rubies that can be seen lying underneath. It is a geographical wonder to see how these rubies, liberated from the parent rocks by erosion and weathering for over thousands of years, have been picked up by water and, due to their high specific gravity and hardness, trapped and concentrated in certain locations along current or former river beds. We dig our nails on the walls of these pits to extract some rubies manually and after a few minutes I have already mined a handful of pink rubies! Even as I am basking in the feeling of being a queen, what with so many of these Mozambican rubies with me, an announcement jolts us back to reality as the officials ask us to throw these rubies back to the soil. Alas!

The stringent security check that follows thereafter is proof of the advisory. For, not only are we thoroughly checked by two lady officers who make us remove our shoes, socks and even check the web of our feet, we are taken to an adjoining room for further inspection of the body, including the mouth, just in case some smart one has popped a ruby inside. Mind you, it’s not just visitors but every employee walking into the mine and stepping out has to go through this rigour at least 4-5 times and at each zone within the mine. Rahul, the security head at MRM and an ex-Indian army officer, monitors every move within the mines to ensure illegal miners and smugglers are kept at bay, be it during the day or night.

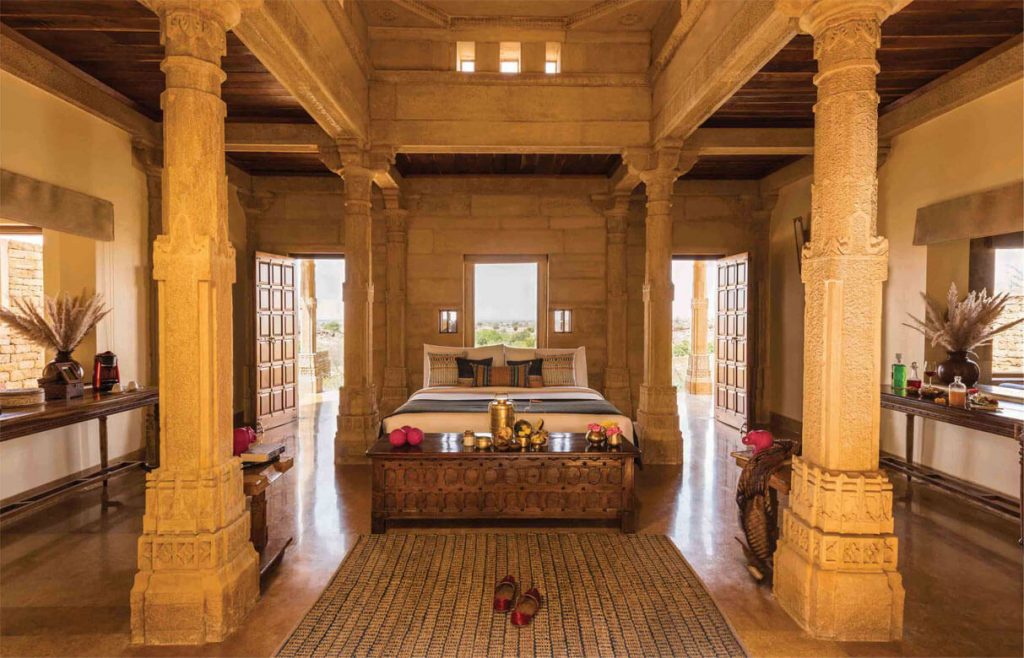

By afternoon we return to the comfortable confines of the camp. Here, rows of large containers that double up as office space are preceded by the newly-built cottages earmarked for senior officials of MRM. We happen to the first guests to enjoy the luxury comforts of this well-equipped lodging facility, a cosy place to return to after the day’s rigorous toil.

Gemfields’ efforts towards sustainable mining finds echo in its adoption of five villages and taking it upon itself to educate the village children, offer skill training to elders, assist them in implementing better agricultural practices, offer medical facilities, and provide them employment within the camp; be it for cooking, cleaning, housekeeping services, gardening and security. Planting trees, restoring the top soil and recycling the waste water are some of its eco-friendly initiatives that reflect the long-term vision of Gemfields towards the betterment of this region.

Day 2 takes us to the wash plant where the gravel bed material recovered from the auger drilling is weighed, before being put through a small, portable jig. The washed material is then re-weighed and sent to the sort house to record any recovered rubies.

The sorting house can be called the prime zone within the mines. It is here that the coloured gems are brought. Here, locals as well as young students of geology are busy sorting the stones by hand. With their white gloved hands slid inside the twin holes of a glass covered box, they are busy sorting the pile of raw stones that have been weighed and kept on their table. Like a carrom board, the holes on each side of the table ensure the stones are categorised: rubies, garnet and waste. The waste is discarded, the garnets stockpiled for future use, while the rubies are further split into various quality and size categories in the next room. We get to see the different grades, size and colours of rubies, sapphires, corundum and garnet and are told how these Mozambican rubies, with their trademark pink colour, is unlike the red-coloured Burmese rubies. Little wonder, the commercial viability of these Mozambican rubies has caught the fancy of both bulk buyers and well-known luxury jewellery houses alike. So, the next time you see a jewellery piece that boasts a Mozambican ruby, you know its genesis.

Gemfields (www.gemfields.com)